The Potential of 3D Printing in Manufacturing and Prototyping

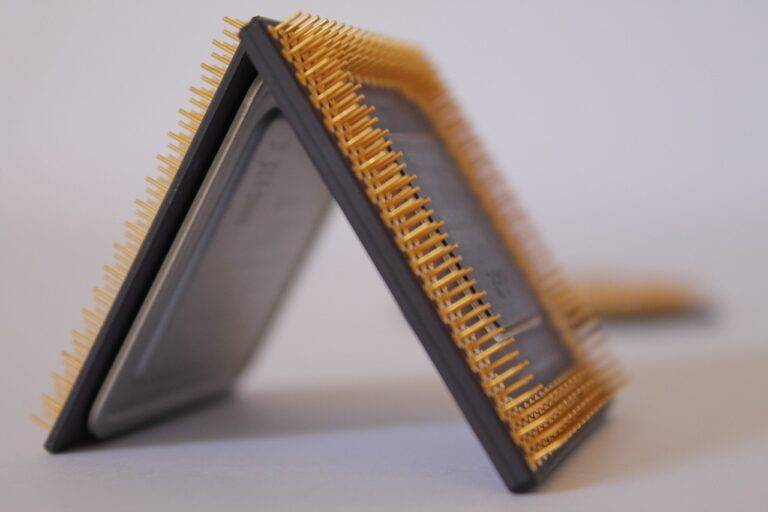

3D printing in manufacturing offers numerous benefits to companies seeking to streamline their production processes and innovate their product development strategies. One of the key advantages is the ability to create complex and customized parts with intricate designs that may not be achievable through traditional manufacturing methods. This opens up endless possibilities for manufacturers to cater to specific customer needs and requirements, giving them a competitive edge in the market.

Moreover, 3D printing in manufacturing also significantly reduces lead times by accelerating the prototyping and production phases. With the ability to rapidly produce functional prototypes and iterate designs quickly, companies can bring new products to market faster and stay ahead of the competition. This speed and flexibility in the manufacturing process not only enhances efficiency but also allows for cost savings in the long run.

• 3D printing allows for the creation of complex and customized parts with intricate designs

• Catering to specific customer needs gives companies a competitive edge in the market

• Accelerates prototyping and production phases, reducing lead times

• Rapid production of functional prototypes enables quicker iteration of designs

• Bringing new products to market faster helps companies stay ahead of the competition

Impact of 3D Printing on Production Processes

With its ability to rapidly produce complex designs and customized products, 3D printing has revolutionized production processes in various industries. Traditional manufacturing methods often involve multiple steps and tooling processes, leading to longer production timelines. However, 3D printing enables the creation of intricate parts in a single process, reducing lead times significantly. This efficiency not only speeds up production but also allows for greater flexibility in design modifications, leading to enhanced product development cycles.

Moreover, the accuracy and precision of 3D printing play a crucial role in improving the quality of manufactured components. By utilizing computer-aided design (CAD) software, manufacturers can create detailed models that are directly translated into physical objects with minimal margin for error. This level of precision ensures that each product meets the required specifications, resulting in higher quality outputs and reduced defects in the production process. The integration of 3D printing in production processes has thus optimized manufacturing operations by streamlining workflows and enhancing product quality.

Cost-Effectiveness of Using 3D Printing in Prototyping

For many industries, utilizing 3D printing technology in the prototyping phase has proven to be a cost-effective solution. Traditional prototyping methods often involve high costs due to the need for specialized tools, equipment, and skilled labor. With 3D printing, companies can significantly reduce these expenses by producing prototypes in-house using relatively inexpensive materials.

Furthermore, 3D printing allows for quick iterations and modifications to prototypes without the need for retooling or lengthy production times. This agility in the prototyping stage can lead to faster product development cycles and ultimately reduce time-to-market for new products. As a result, companies can save money by avoiding delays and costly revisions that often arise with traditional prototyping methods.

How can 3D printing benefit manufacturing processes?

3D printing can streamline production processes, reduce lead times, minimize material waste, and enable rapid prototyping.

What is the impact of 3D printing on production processes?

3D printing can revolutionize production processes by allowing for more customization, on-demand manufacturing, and increased flexibility in design iterations.

Is using 3D printing in prototyping cost-effective?

Yes, using 3D printing in prototyping can be cost-effective as it reduces the need for expensive tooling, shortens lead times, and allows for quick iterations without incurring additional costs.

Can 3D printing help in reducing production costs?

Yes, 3D printing can help in reducing production costs by eliminating the need for traditional manufacturing processes, reducing material waste, and optimizing production workflows.

Are there any limitations to using 3D printing in prototyping?

While 3D printing has many benefits, it may not be suitable for mass production due to limitations in speed and material options. Additionally, the initial investment in 3D printing technology can be costly.